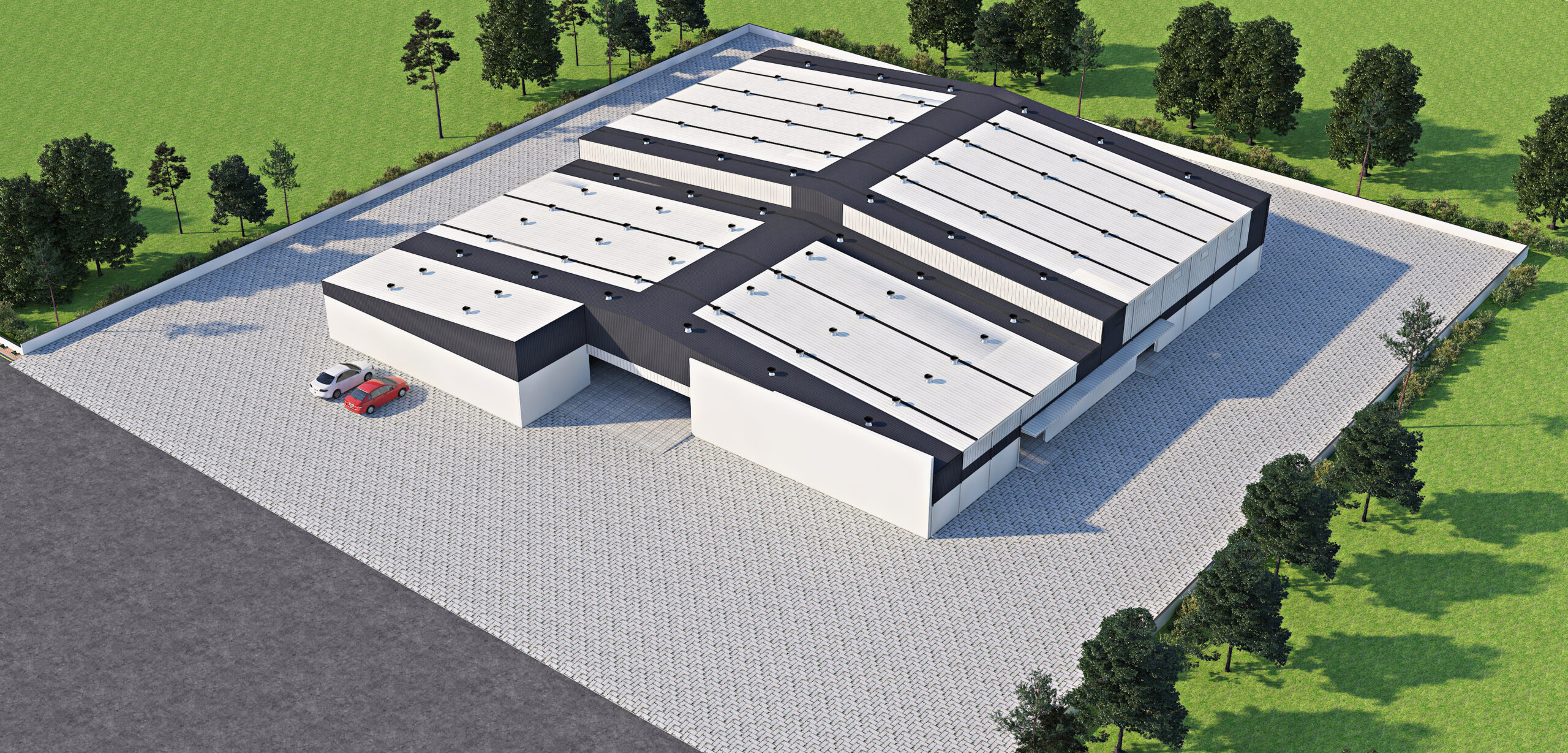

Our Facilities

We Normally Purchase All Commodities From Harvesting Areas (Known As "APMC/MANDIS") From All Over India. Our Processing, Cleaning Unit & Warehouse Is Situated Close To Mundra & Pipavav Port. It Is Well Connected By Road, Which Facilitates Faster Delivery Of Goods To Our Warehouse From All Parts Of India. The Goods Delivered To Our Warehouse Are Stored In Ideal Conditions.

Raw Material Storage

Products are Stored in a Dry and Ventilated In-House Warehouse. Pest Control is carried out as per Required Interval. The Warehouses Have a Natural Ventilation System For Removal Of Heat And Excess Moisture From The Product As They Cure And Reach Moisture Equilibrium.

Pre-Cleaning

Dust, Stones, Mud, Sand, Leaves, Shrivelled & Undeveloped Pods, Small Inshells, And Any Other Foreign Materials Are Removed from Related products in the cleaning Section.

This Is Used To Clean Any Kind of Agriculture Whole Oil Seeds & Spices Products, Where Goods Are Sold As Per Their Count.

De-Stoner

Gravity De-Stoner Is Used to Separate Related Products from Stone, Mud Metal, Glass, And Other Heavy Impurities Based on Different Gravity of Materials, i.e. Impurities Which Are Heavier than Product As well As Light Air Borne.

Gravity Separator

Relevant Products Are Cleaned By a Gravity Separator Which Separates Impurities, Shrivelled Seeds, Light Seeds, Pods, And Damaged Seeds Etc. This Operation Ensures That Only Good Quality Material Go Further In The Process.

This Unit Is Used To Separate Light Air Borne Particles And Hollow Or Immature Seeds As Well As Grading Of Material By Size.

Sorting Operation

In This Process, Relevant Products Are Graded By Their Colour To Ensure A Uniform Appearance For Added Value. This Operation Results In the Reduction Of Microbiological & Aflatoxin Levels Through The Efficient Removal Of Discoloured, Diseased And Damaged Seeds.

Uniform Grading

In This Operation, Seeds Are Graded As Per The Count Specified By The Buyer In Three Stage Uniform Grading Process.

Metal Separation

Metal Separator Detects and Separates Any Kind Of Metallic Foreign Material before Packing of the Final Product.

Pre Shipment Lab. Analysis

We Have Tied Up With the Majority of Reputed Laboratories / Inspection Vendors For Testing Of Various Parameters As Per Buyer Requirements Like Pesticides, Salmonella, E. coli, Aflatoxin, FFA, Oil, Purity, Impurity, Admixture, Etc. For a Few Of Them, We Have Our In-House Lab. Facilities/Equipment For Testing Parameters Like Aflatoxin, Moisture, Purity, Impurity & Admixture.

Packing

We Offer From 10 Kg. To 50 Kg. Packaging in Food Grade PP / Paper /Jute Bags as Per Specific Importer Labelling/Marking.

All Required Packing are Fulfilled By Our Trained Workers Directly Stuff Goods Into The Container At Our Factory Premises Under Expert Supervision And In A Scientific Manner. Thus The Chances For Any Sort Of Pilferage Or Weight Shortage Are Minimized.

Ethylene Oxide (ETO) Sterilization

We Have an In-House Facility for ETO Sterilization and the same is applied as per Importing Country Norms & Buyer Requirements. To Achieve These Objectives, We Are supported By a Qualified Team of Quality Controllers who closely supervise the Entire Process of Processing, Filling, Weighing, and Packing. The Professionals Ensure That the Range of Products Supplied is of High Quality and contains no Added Artificial Flavour, Chemicals, Etc.

Some Factors That Have Helped Us in Becoming Leader in Our Products:

- Procuring Good Quality Raw Material Products

- Processing On Basis of Tremendous Experience

- Superior Packaging Standards

- Containerization of Export Cargo

- Timely Delivery of Products in Any Corner of the World

- Economical Pricing

- Customer-Focused Approach

- Own In-House Lab. Facilities/Equipment For Testing Parameters Like Aflatoxin, Moisture, Purity, Impurity, and Admixture

Processing Unit : 1

Processing Unit : 2